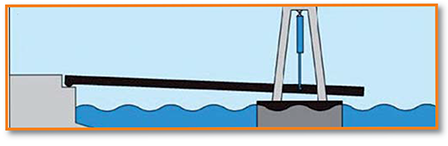

RoRo facilities:

Hydraulic Linkspan The linkspan is mounted to a frame suspended on piles. A hydraulic system raises and lowers the linkspan to accommodate variations in the tide and the vessel’s threshold. The height of the linkspan automatically responds to the vessel’s movements. Safeguards are incorporated in the design of the facility to protect the unit and its users in the event of a loss of hydraulic pressure. Options to protect the landing stages from considerable damage of a collision can be found in a fender system attached to the front of the bridge or ramp, an overrun structure at the bridge attachment to the quay and/or a floating fender positioned in the front of the linkspan.

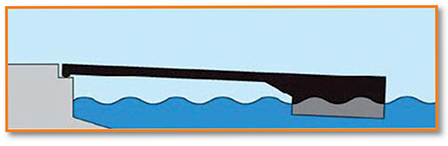

Linkspan Floater

The bridge is attached to the pontoon with a fixed connection, enabling the pontoon to rise and fall with the tide. The bridge provides access at a gradient within the specified angle of inclination. Changes in the freeboard can be accommodated using a ballast system (automatic) with fixed connections between the bridge and the pontoon. Survey on different linkspans has shown that this solution is the most secured way of loading and unloading a ship.

Options to protect the landing stages from considerable damage of a collision can be found in a fender system attached to the front of the pontoon or ramp, an overrun structure at the bridge attachment to the quay and/or a floating fender positioned in the front of the linkspan..

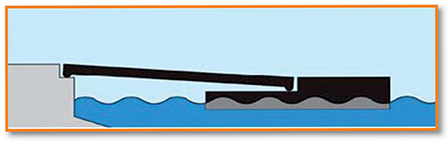

Floating Linkspan

The bridge is attached to the pontoon with a hinged connection, enabling the pontoon to rise and fall with the tide. The bridge provides access at a gradient within the specified angle of inclination. Changes in the freeboard can be accommodated using a ballast system (automatic) with fixed connections between the bridge and the pontoon. Survey on different linkspans has shown that this solution is the most secured way of loading and unloading a ship.

Options to protect the landing stages from considerable damage of a collision can be found in a fender system attached to the front of the pontoon or ramp, an overrun structure at the bridge attachment to the quay and/or a floating fender positioned in the front of the linkspan.

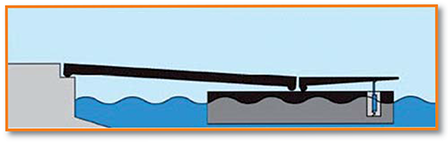

Combined Linkspan

A hydraulically-operated ramp attached to the floating pontoon adjusts the pontoon’s freeboard to the vessel’s threshold. In this design the hydraulic cylinders are located under the movable ramp, a feature which is beneficial to the safety of the structure. The pontoon ensures that the freeboard remains constant and consequently virtually no further operations of the ramp’s controls are required during the loading and unloading of the vessel. This construction is also ideally suited to double-tier linkspans.

Options to protect the landing stages from considerable damage of a collision can be found in a fender system attached to the front of the pontoon or ramp, an overrun structure at the bridge attachment to the quay and/or a floating fender positioned in the front of the linkspan.

Wij voldoen aan alle geldende normeringen en zijn ISO9001 gecertificeerd.

retrobridge ro-ro en pontoons

Specialist en leverancier in toonaangevende brugsystemen

Hoge staalkwaliteit & (de)montage service

Permanente, tijdelijke en noodbrug oplossingen op maat

Gecertificeerd aanbieder modulaire bruggen in Europa

“Retrobridge gaat elke brug uitdaging aan”

Hoe kunnen wij uw uitdaging overbruggen?

retrobridge ro-ro en pontoons. The linkspan is mounted to a frame suspended on piles. A hydraulic system raises and lowers the linkspan to accommodate variations in the tide and the vessel’s threshold. The height of the linkspan automatically responds to the vessel’s movements. Safeguards are incorporated in the design of the facility to protect the unit and its users in the event of a loss of hydraulic pressure.

CONTACT MET ONS

T: +31 (0)73 640 87 70

E: sales@retrobridge.com

A: Bruistensingel 120

5232 AC ‘s-Hertogenbosch